SIFCOR group

"The Automobile is currently undergoing a new technological transition to meet societal and environmental expectations.

With its technical solutions and its various areas of expertise, SIFCOR wants to be at the heart of this revolution by offering advantages in terms of reliability, security, robustness, lightness, size, modularity and recyclability, characteristics specific to the forge trade.

With the involvement of its employees, its technical system, its research and development as well as its international deployment, SIFCOR is, by its nimbleness, the preferred partner of automobile manufacturers and equipment manufacturers in its multiple fields of expertise."

Jean-Louis and François DEGUY

Our business

The SIFCOR group, through its various subsidiaries, manufactures steel forgings in large or medium series, intended for the automobile, truck and motorcycle markets, by:

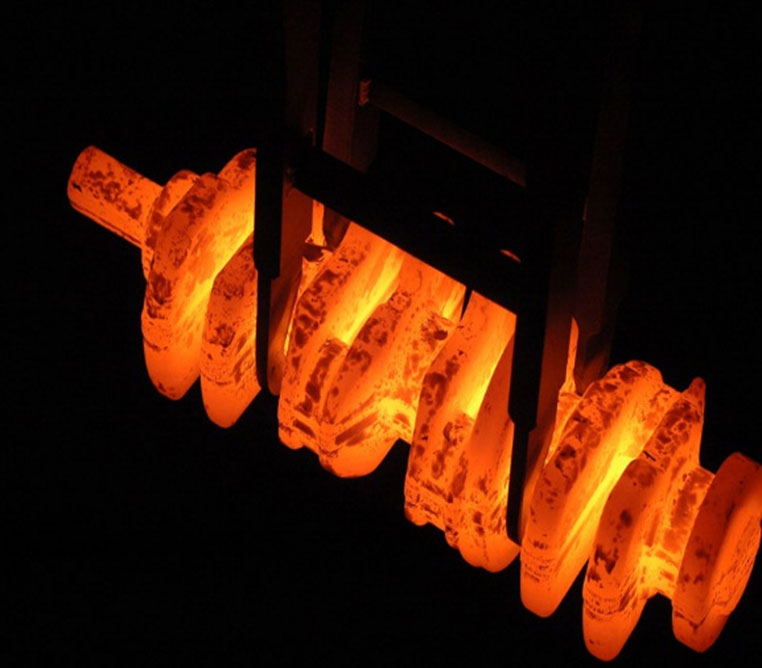

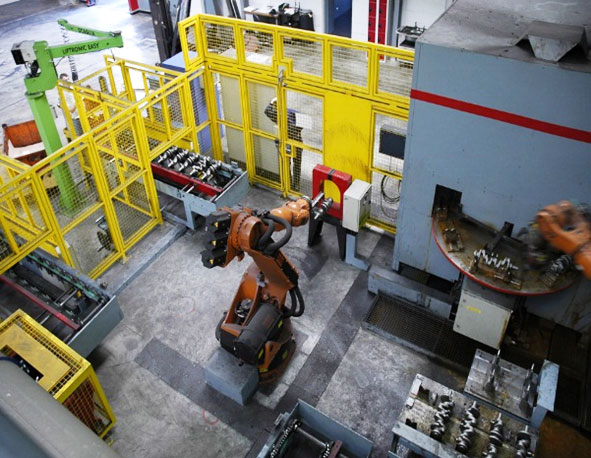

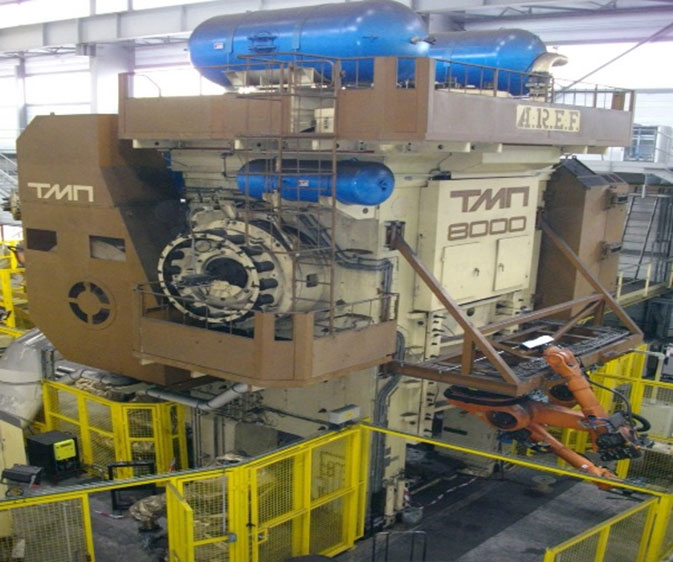

- Hot stamping on mechanical presses or robotic rams for the suspension, engine and transmission,

- Warm or cold extrusion, for the differential case, the gearbox, the engine, the suspension and transmission

- Heat treatment, Coating, Machining, Assembly.

Amis

Manufacture of pinions for differentials, gearboxes, engines and transmission parts by cold and warm forging, machining, heat treatment and assembly of parts (for long production runs).

Forges de Courcelles

Manufacture of steel parts for suspensions, engines and transmissions by stamping, hot or warm forming, on either fast rams or robotic mechanical presses, integrating, depending on the criteria selected, heat treatment, coating, machining and assembly.

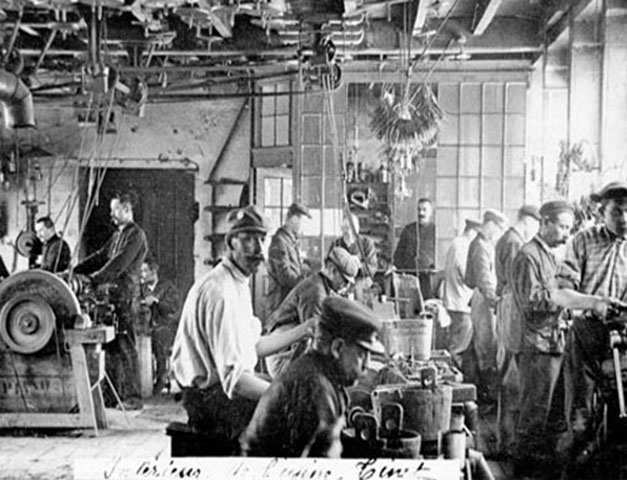

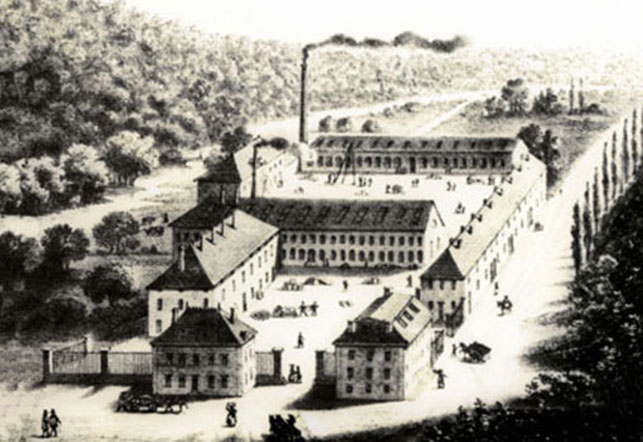

History

SIFCOR is a family-owned group founded in the 1880s, with the establishment and modernization of industrial means for the manufacture of cutlery preforms in Nogent in Haute-Marne. Very quickly though, the Group turned to other fields of activity, including the automobile industry, which has considerably developed since the 1950’s, representing currently the main part of its activity.

Today, the SIFCOR Group is made up of two subsidiaries representing the two main phases of technological integration and evolution.

Starting with drop forging for parts with medium sized production runs, then integrating warm forging by extrusion in the 1970’s for long production runs, SIFCOR is bringing about changes in the forging industry in order to meet the high demands in the field it has devoted itself to.